Margel 580 is based on a patented combination of 3 corrosion inhibiting chemicals that provide protection to steel and other metals.

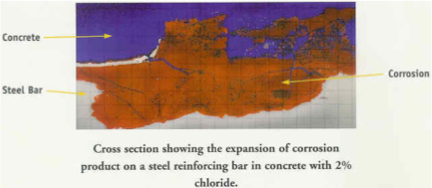

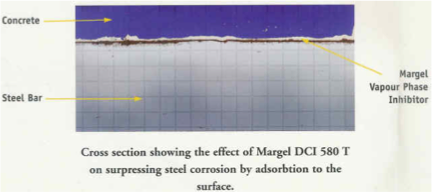

During the initial development and testing of the product multiple tests were carried out both in the laboratory and on live sites, and the effects on corrosion were monitored until the combination of chemicals was perfected. The tests were measured in several different ways, including half-cell measurements of the concrete structures and detailed analysis using a scanning electron-microscope of the embedded steel. Once the engineers were satisfied with the in-house results the products were tested by an independant laboratory.

Makers Industrial Ltd and QED jointly commissioned an independent test to verify whether it is possible for a corrosion inhibitor to migrate through concrete.

Samples of Margel VPI 580 where submitted for testing to Geomaterials UK

The

Conclusion Summarised by Dr French BSc, PhD, FGS of Geomaterials was;

"It is clear that Margel does travel through a concrete pore structure, or more precisely, each element

of the product does"

"Each

active ingredient contains a known corrosion inhibitor with an industry track

record of inhibiting corrosion, we can verify that this readily travels through

dense structural concrete"

Subsequent tests have proved that once Margel 580 is inserted into the core structure of a building suffering from corrosion effects, the resultant change from a "corroding state" to a "non-corroding state" can be measured using "half-cell" techniques.

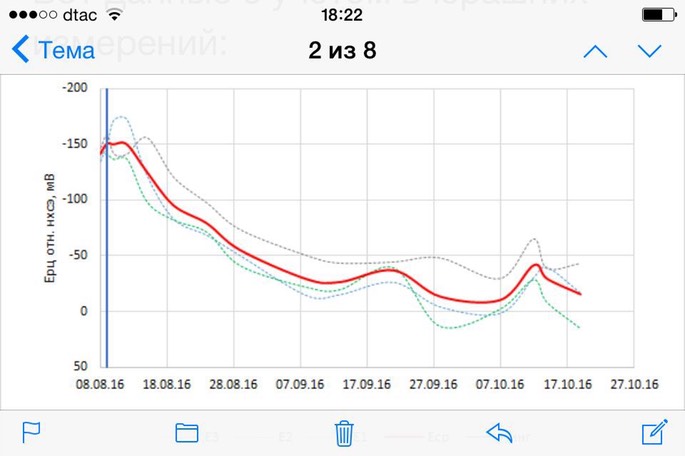

In the diagram below we have the pre-publication results from current testing being carried out in Moscow, which clearly demonstrates effectiveness of Margel 580 cartridges.

Red line shows average half cell reading from slab under test. Blue vertical line shows date Margel 580 cartridge inserted. Initial reading is -150, showing corrosion active in reinforcement steel of slab. Over a period of 2 months, the reading improves to close to 0; results are still being scientifically interepreted and are due in Spring 2017, but corrosion threshold is estimated to be over -50.

More details to follow;