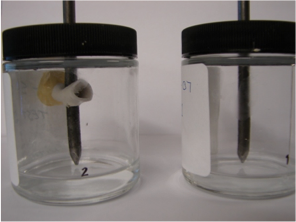

QED regularly test the chemicals used in the manufacture of the Margel 580 cartridges. A test in the pictures below visually shows the chemical working as a highly effective corrosion inhibitor;

In this test 2 glass jars were taken with a small amount of water in the bottom, mild steel nails were suspended from the lids. The jar on the left has a small qty of Margel in the air space, the jar on the right with nothing.

This picture clearly shows that after 9 months, the nail without any protection (LHS) is corroding significantly whilst the nail protected by Margel (RHS) has no corrosion.

The same test using an expiremental expanding foam containing Margel;

25th March 2008

34 years on and Margel still protecting steel surface!!!

Some original nail tests were carried out as a simple example of Margel 580, these were sealed in test tubes in 1983, these pictures were taken in 2010 - 27 years after being sealed. The cork has dried up and the margel from the top jar has evaporated. But the protection can be clearly seen, as the nail in the top tube still has a shiny surface area of metal showing and shows no signs of delamination. The nail in the 2nd tube was sealed without any corrosion inhibitor, this corroded significantly and has expanded to almost 300% of its original volume with no structural integrity left. Whilst this is not re-inforcement bar in concrete, it proves a very simple fact of the protection given by the Margel 580 and what would happen to a structure if the rebar expanded by 300%!

Above - nail was sealed with a small qty of Margel 580 in 1983

Below - this nail was sealed with no corrosion inhibitor in 1983